Call us

08045477572

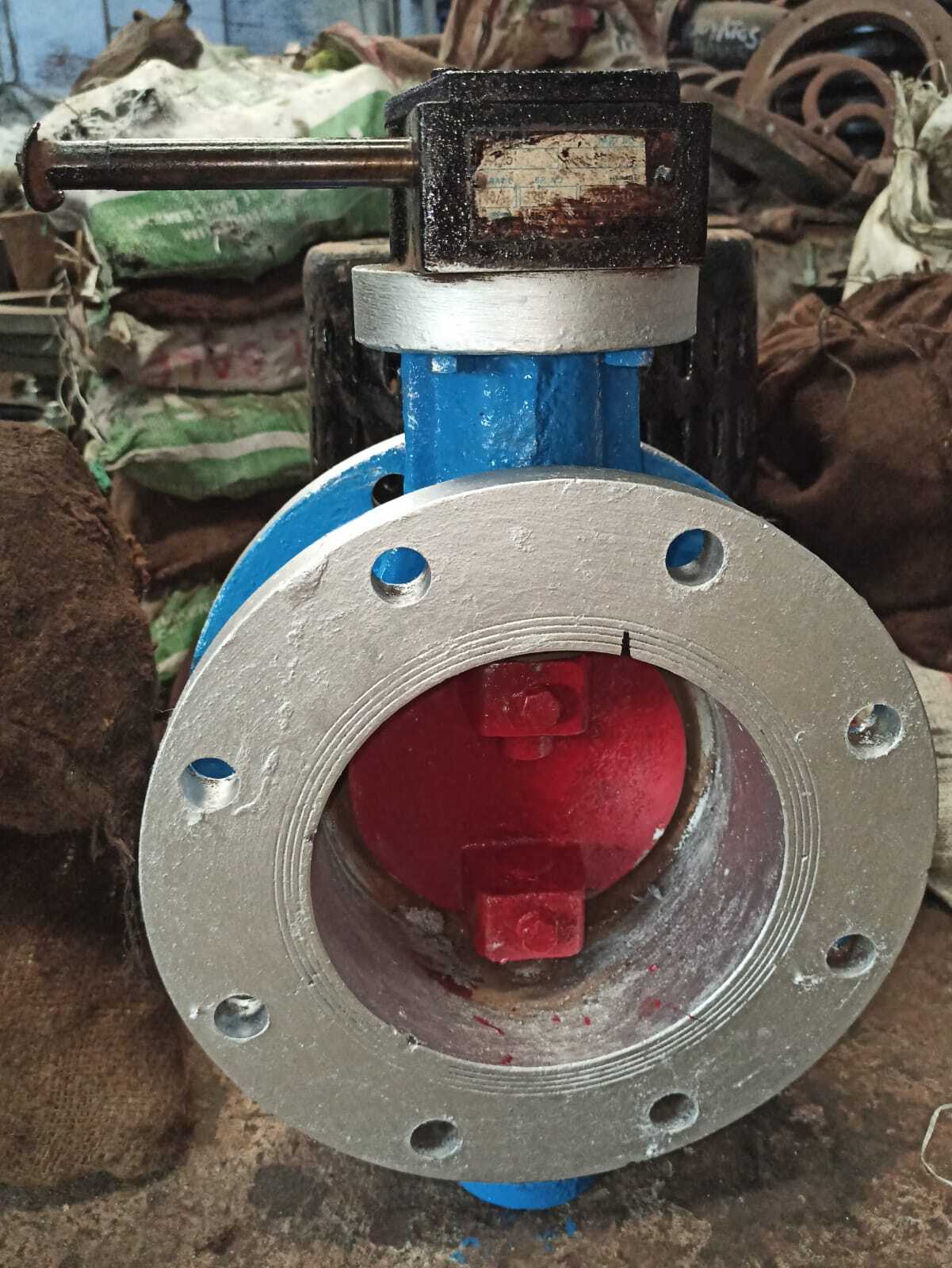

Buy from us manually operated Butterfly Valve that is designed to control the flow rate within the pipelines as per the system requirement. This inline type fitting is manufactured by using top-grade materials which result in high strength and rigidity to bear extreme pressure and temperature that ultimately leads to longer service life. The offered Butterfly Valve has a flanged body fr easy installation with the help of mechanical fasteners. Buy from us this heavy-duty valve in bulk at a low price range.

We are manufacture of Cast Iron Wafer Type Butterfly Valve As per IS : 13095/91.

|

Description |

MATERIALS & SPECN |

|

Body |

CAST IRON IS:210 FG-200 |

|

Disc (Epoxy coating) |

CAST IRON IS:210 FG-200 |

|

Hand wheel |

CAST IRON IS:210 FG-200 |

|

Shaft |

S.S., AISI-410/304/316 |

|

Seat |

NITRILE/EPDM/VITION |

|

Pin |

S.S., AISI-304 |

|

Lever |

C.I. / M.S. |

|

Bush |

G.M./Brass |

|

Shaft seal |

RUBBER O RING |

|

Gear unit |

C.I. IA : 210 FG-200 |

|

Indicator |

ALUMINUM |

Construction of materials as specified in the drawing are standard specification which may be provided other than standard.

Manufacturing range -50 mm to 300 mm NB,

50mm to 150mm NB, lever operated, 200mm and above, gear operated

Price:

Price 500 INR / Piece

Minimum Order Quantity : 100 Pieces

Structure : Other, Direct Acting / Pilot Operated

Material : Brass / Stainless Steel

Port Size : 1/8 Inch to 2 Inch

Disc : Brass / Stainless Steel

Price 500 INR / Piece

Minimum Order Quantity : 100 Pieces

Structure : Other, Pilot operated / Direct acting

Material : Cast Iron, Cast Steel, Stainless Steel, Brass

Port Size : 1/2 inch to 4 inch

Disc : SS304 / SS316 / EPDM

Price 500 INR / Piece

Minimum Order Quantity : 100 Pieces

Structure : Other, Single Body with Flanged Ends

Material : Brass Body

Port Size : 1/2 inch

Disc : Stainless Steel

Price 500 INR / Piece

Minimum Order Quantity : 100 Pieces

Structure : Other, Single Plate/Disc

Material : Cast Iron/Brass/Polypropylene (As per model)

Port Size : 1 inch to 6 inch (Standard)

Disc : Stainless Steel or Brass