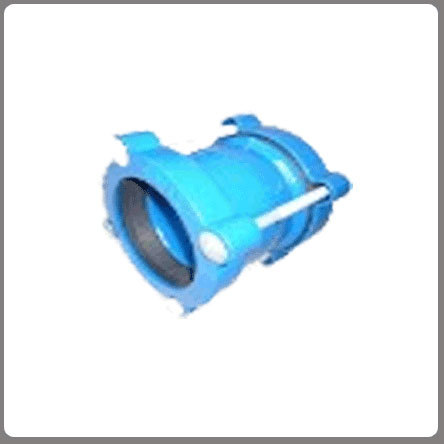

About CI And DI Mechanical Joint Fittings

Explore the new release of CI and DI Mechanical Joint Fittingsengineered for impeccable performance in underground and harsh environments. With top-tier corrosion resistance, dominant impact resistance, and immaculate leakage ratings, these fittings excel in the toughest applications. Designed for push-on, mechanical, or flanged joints, installation is made easy without welding. Each fitting is factory-tested to 1.5x rated pressure and crafted from premium Cast Iron or Ductile Iron, complying with IS and BS/EN standards. Offered in a variety of shapes, sizes, and coatings, these fittings guarantee a design life of 50 years with minimal maintenance, making them ideal for modern water, sewage, and industrial pipelines.

Versatile Commercial Applications for CI and DI Mechanical Joint Fittings

CI and DI Mechanical Joint Fittings are dominant in commercial projects requiring robust, leak-free connections. Their usage spans water supply networks, sewer lines, firefighting installations, and industrial pipelines where stability and reliability are priorities. Suitable for diverse configurationselbows, tees, couplings, flanges, reducers, bends, caps, and socketsthese fittings are designed for both new installations and upgrades. Their immaculate performance ensures seamless integration into various commercial and municipal systems, offering a dependable solution for challenging environments.

Sample Policy and Secure Shipping for Mechanical Joint Fittings

Experience our commitment to customer satisfaction through a transparent product sample policy. Samples of CI and DI Mechanical Joint Fittings are available for evaluation at a sale price, allowing buyers to assess quality and compatibility before bulk orders. Goods transport is managed through secure shipping with each fitting carefully packed in wooden boxes or pallets. Delivery times are prompt and reliable, ensuring your goods reach their destination swiftly and safely, supporting your project deadlines.

FAQs of CI And DI Mechanical Joint Fittings:

Q: How do I install CI and DI Mechanical Joint Fittings in an underground pipeline?

A: CI and DI Mechanical Joint Fittings are designed for ease of assembly, allowing installation without welding. Simply use the push-on or mechanical joint types and follow the provided guidelines for gland and gasket fitting to ensure a secure, leak-free connection.

Q: What environments are these fittings suitable for?

A: These fittings are engineered for underground, water supply, sewage, firefighting, and industrial pipeline use. High corrosion and impact resistance make them suitable for harsh or demanding environments, including those with fluctuating temperatures or exposure to aggressive soils.

Q: When can I expect delivery of my order after purchase?

A: Delivery time depends on order volume and destination. However, we prioritize efficient goods transport and secure packing, typically dispatching your fittings quickly to meet your project timeline. For sample requests, prompt shipping ensures you can evaluate the product ahead of larger orders.

Q: Where are these fittings manufactured and exported from?

A: We manufacture, supply, and export CI and DI Mechanical Joint Fittings from India, distributing them to commercial, municipal, and industrial clients worldwide, adhering to international standards for quality and performance.

Q: What is the benefit of using mechanical joints over welded fittings?

A: Mechanical joints offer significant benefits, including quick and simple installation, the ability to tolerate minor misalignments, and ease of maintenance. They also provide robust, enduring seals with high leakage resistance without the need for welding, thus reducing labor time and project costs.

Q: How can I request a product sample before placing an order?

A: To request a sample of CI and DI Mechanical Joint Fittings, contact our sales department. Samples are available at a competitive sale price, shipped securely for your review before committing to a bulk purchase.